A Printing Partnership

Azul 3D collaborated with the MLDS program in a union that allowed students to gain industry experience and helped the company accelerate its machine learning knowledge.

James Hedrick (PhD ‘19) wanted partners ready to help shake up the status quo.

He found that in a group of students in Northwestern Engineering's Master of Science in Machine Learning and Data Science (MLDS) program (formerly the MSiA program).

Hedrick is co-founder and chief product officer at Azul 3D, a company he created in 2016 as a doctoral candidate in Northwestern professor Chad Mirkin’s research lab. Hedrick and Azul recently partnered with MLDS students on a project to improve the company’s proprietary 3D printing process.

“We work on projects where we have a partner with an opportunity to disrupt the market they are in,” said Hedrick, who earned his PhD in chemical and biological engineering. “These opportunities are specific in nature, creating custom solutions to solve hard engineering challenges and enable improved supply chains and higher performing products.”

Hedrick credited the MLDS program with preparing students to be the disruptors needed in business today. The program strongly emphasizes collaboration with industry partners to give students the opportunity to hone their skills on issues of significance to corporate clients.

Azul has partnered with the MLDS program on multiple projects in the past. Hedrick is consistently impressed by the caliber of the program’s students.

“The MLDS students are dedicated, professional, and informative,” he said. “They provide impactful data-driven insights, clear communication about their process, and define the range of opportunities given the resources they are provided.”

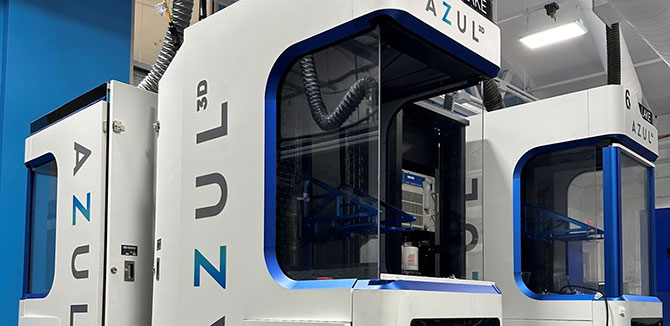

Azul has garnered attention since its founding for its innovations in 3D printing, ranging from pandemic-motivated face shields to pickleball paddles. The company’s mission is to streamline the process of taking ideas from prototype to manufacturing at a low cost.

Its proprietary High-Area Rapid Printing (HARP) technology uses ultraviolet light to convert liquid plastic into solid objects at rapid speeds.

That rapidity was vital to the company’s survival and success as the COVID-19 pandemic swept across the nation. When there was a sudden need for personal protective equipment, the company pivoted to producing face-shield parts, developing a prototype in just 24 hours, and enough components in 48 hours to make 1,000 shields per printer per day.

Since then, the company has received accolades for its partnership with early investor DuPont and its work with sports equipment manufacturer Wilson. With the latter partnership, the Azul's ability to customize layers of material created a pickleball paddle that reduces some of the loud thwacking noises associated with ball striking.

Hedrick was excited to partner with his alma mater.

“We wanted to collaborate in order to optimize our printing process and how to achieve quality results utilizing a data-driven approach,” Hedrick said. “The MLDS program prepares students by helping them understand both the prospects and challenges of machine learning and data science in industry applications.”

The students’ biggest benefit is getting the chance to work with actual data sets instead of theoretical numbers generated for a classroom exercise. Academic collaboration benefits companies such as Azul 3D in multiple ways, as well.

“There has been a lot of buzz about artificial intelligence and machine learning lately and how that is changing the landscape of businesses,” Hedrick said. “Collaborating with MLDS has accelerated our understanding and adoption of this. At the same time, it has given us a great pipeline of highly qualified candidates.”