The Problem

Worker fatigue in safety-critical industries like manufacturing increases the risk of accidents and injuries while decreasing overall performance.

Worker fatigue in safety-critical industries like manufacturing increases the risk of accidents and injuries while decreasing overall performance.

The interdisciplinary engineering team developed a wearable multimodal sensor system that leverages machine-learning to enable near-real-time fatigue prediction on the factory floor.

Factory decision-makers could make use of fatigue prediction information to implement operational interventions, adaptive work schedules, and adjust work/rest cycles to minimize fatigue-related incidents or performance loss.

Professors Jian Cao, Ping Guo, John Rogers, Shuai Xu, Qi Zhu; QSIB director of engineering research Anthony Banks; PhD students Vasudev Aravind, Marisa Bisram, Payal Mohapatra; former postdocs Hyoyoung Jeong and Katherine Jinkins; and Young-Joong Lee (’22).

According to a 2018 National Safety Council report, 63 percent of manufacturing workers report feeling tired at work, increasing the risk of accidents and injuries while decreasing overall performance. In addition, 89 percent of manufacturing employers report the impact of labor-induced fatigue, with 73 percent reporting decreased productivity and 44 percent linking safety incidents with fatigue.

Aiming to improve occupational health among manufacturing workers, Northwestern Engineering’s Ping Guo and Qi Zhu led a team of multidisciplinary researchers in the development of a wearable multimodal sensor system that leverages machine learning to enable near-real-time fatigue prediction on the factory floor.

Factory decision-makers could make use of such information to implement operational interventions, adaptive work schedules, and adjust work/rest cycles to minimize fatigue-related incidents or performance loss.

While there are no universally recognized biomarkers or metrics to quantify physical fatigue, the team aimed to develop a suitable representation that is informative for industrial settings while being considerate of workers' well-being, comfort, and privacy.

“In other fields, such as sports science and knowledge work, fatigue is often oversimplified as a binary state (fatigue or non-fatigue). However, for manufacturing operators, a more nuanced approach is required,” said Guo, associate professor of mechanical engineering at the McCormick School of Engineering. “Our system relies on privacy-preserving, unobtrusive sensing modalities, paired with lightweight analytics suitable for on-device deployment.”

The soft, flexible sensors continuously monitor vital signs, including heart rate and skin temperature, as well as locomotive signals. Manufactured by Sibel Health, the sensors were developed by the Querrey Simpson Institute for Bioelectronics (QSIB) and the research group of John Rogers, Louis Simpson and Kimberly Querrey Professor of Materials Science and Engineering, Biomedical Engineering, and Neurological Surgery, and QSIB director.

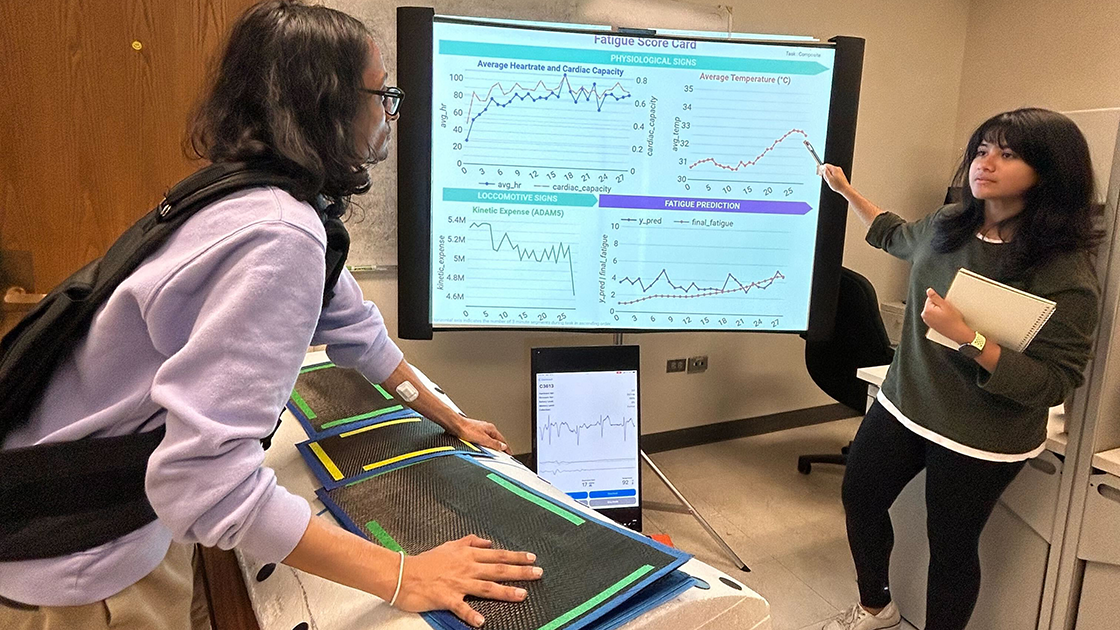

The sensor data — which accounts for person-specific attributes (such as age, gender, height, and weight) — is transmitted to the user in near-real-time via a “Fatigue Score Card” visual dashboard.

“Our system’s practical applicability enables companies to leverage this sensor framework to preemptively address worker fatigue and reduce operational losses,” said Zhu, a professor of electrical and computer engineering and (by courtesy) computer science at Northwestern Engineering. “At the same time, this represents a significant step toward improving manufacturer worker safety with potential applications in other sectors involving physical motion and fatigue, such as sports and medicine.”

Simulating a manufacturing environment, the research team collected the training data for the prediction model in a laboratory setting at Northwestern University. Subjects completed two hour-long strenuous and repetitive manufacturing tasks involving intricate steps while wearing six sensors on their torso and arms. The participants submitted surveys after each task iteration and rest period to gauge their perceived state of fatigue from zero (no fatigue) to 10 (max fatigue). The system was then tested at two manufacturing facilities.

The research team gained valuable insights, notably that the kinetics of an operator’s nondominant arm is a prominent indicator of fatigue, independent of the specific task being performed.

The team designed the machine learning model to prioritize operator-centric analytics through a custom asymmetric loss function that significantly reduces the underprediction rate.

“Predicting a perceived fatigue score is very difficult,” Guo said. “We ensured that our model does not underpredict the fatigue a worker may perceive, as this could convey incorrect information to both the organization and the individual, potentially leading to overwork despite the worker's fatigue and increasing the risk of injury.”

The research team will continue investigating how to integrate the sensor framework with existing manufacturing workflows, mindful of the complex ethical and legal implications of deploying such systems in real-world workplace environments.

The Northwestern team also included first authors Payal Mohapatra, a PhD candidate in computer engineering, and PhD student in mechanical engineering Vasudev Aravind; PhD student in mechanical engineering Marisa Bisram; Jian Cao, associate vice president for research and Cardiss Collins Professor of Mechanical Engineering; Young-Joong Lee (’22); former Rogers Research Group postdocs Hyoyoung Jeong and Katherine Jinkins; QSIB Director of Engineering Research Anthony Banks; and Shuai Xu, Ruth K. Freinkel, MD, Professor of Dermatology, Pediatrics, and Biomedical Engineering and QSIB Director of Medical Research.

Researchers from Boeing Research & Technology, Deere and Company, and the University at Buffalo also collaborated on the wearable network project, which was published in PNAS Nexus on October 15.