Introducing BotChocolate

Students in the MSR program’s Embedded Systems in Robotics course talk about the challenges of creating a hot chocolate-making machine.

There’s nothing much better in cold weather than kicking back after successfully completing a project and sipping on a cup of hot chocolate – especially if the robot you created for the project made the drink for you.

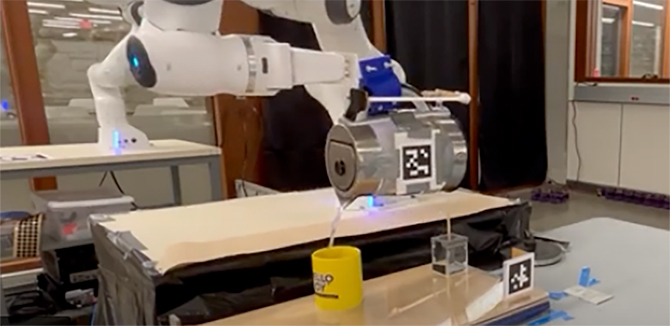

A team of first-quarter students in Northwestern Engineering's Master of Science in Robotics (MSR) program tasted that sweet success this fall after constructing BotChocolate, a hot chocolate-making robot.

“It wasn’t until the robot was really good that we drank any hot chocolate, and our first couple of cups were particularly gross,” said James Oubre, who was part of the five-person team. “Once it was good, we all celebrated with a few cups.”

The robot was developed in Embedded Systems in Robotics, a fundamental course that introduces students to a range of skills and frameworks they will use throughout the MSR program and then in their careers.

Oubre was joined on the BotChocolate project by Shantao Cao, David Dorf, Allan Gracia-Casal, and Nicholas Marks. Oubre said having a team of reliable colleagues was key to BotChocolate’s success and will serve him well after his MSR graduation.

“It gave me experience of how the software pipeline at a company could be like,” he said. “Now I feel comfortable contributing to a code base where I am not the only person working on it.”

Building a robot capable of concocting the perfect cup – or at least a good cup – of hot chocolate isn’t easy, the students learned. The biggest challenge came, in part, because of one of hot chocolate’s main ingredients: water.

The team wanted to keep the liquid away from the computer running BotChocolate while it was learning how to grab a cup and pour it. That meant spacing out their ingredients on a separate table and straining the limits of the Franka Emika 7 DOF robot arm.

Oubre figured handling the ingredients would be an obstacle for the robot.

“I thought the biggest challenge would be being able to accurately pick up and manipulate the different objects," he said. "I worried there would be a lot of issues with the robot not being able to go exactly where it needed to be to pick things up and also precisely pour the water and cocoa in the mug. This ended up not being as big of an issue as I thought it would be.”

The robot's physical limitations did still make the project complicated. The team created software to help the robot identify the positions of different objects, but they quickly learned the importance of testing and not making assumptions based on one success.

"The trajectory the robot would travel to get to the new location would not always be the same, and if the components were in slightly different locations it could significantly change the robot’s path," Oubre said. "This meant we could not always rely on the fact that if it worked once, it would behave the same the next time. We had to put in measures to counteract that."

Eventually, BotChocolate went from clumsily fumbling through the hot chocolate-making process to smoothly turning on a kettle, dumping cocoa powder into a mug, pouring hot water onto the powder, and stirring the mixture with a spoon.

“The most exciting part of the project was definitely the satisfaction of the robot successfully making a cup of hot chocolate,” Oubre said. “Seeing all our work on the software manifest into a physical robot performing a task was very exciting.”

The BotChocolate project is behind the students now, but the lessons they learned during the process are being applied to this day, including on their independent projects.

“This project was an enormous learning experience,” Oubre said. “It was probably the most involved project I have ever done for a course, and I feel my skills would never have been as good as they are now if I hadn’t worked on this project.”